Home

MENU

Enterprise Email Report Mailbox

2005-2019 all rights reserved. Copyright notice eicpb No. 16004507-2 Technical support:QIANYE

2005-2019 all rights reserved. Copyright notice eicpb No. 16004507-2 Technical support:QIANYE

SCIENTIFIC ENTERPRISE FOR

COMPREHENSIVE ENVIRONMENT

GOVERNANCE

Sand is a “potential” threat to wastewater plants. It is deposited at the bottom of the tank, is not easy to detect, and is often overlooked by managers and operators. As the problem slowly builds up, it can become very serious when it erupts. The dangers of sand are manifold, posing many challenges to the normal operation of a wastewater plant, as well as posing a significant safety risk to asset maintenance. Not only reduces the treatment efficiency of the sewage plant, but also increases the operating costs.

At present, the domestic sand removal standards require the removal of gravel of 200μm and above, but in practice, the influent gravel particle size is small, most of the gravel particle size is between 50-200μm, and the traditional technology of sand removal capacity of fine gravel removal ability is seriously insufficient, resulting in a large number of gravel into the subsequent process of the treatment works. In order to solve this problem, the desanding process is divided into three independent units of concentration, sand washing and dewatering during the process design, and strengthened separately.

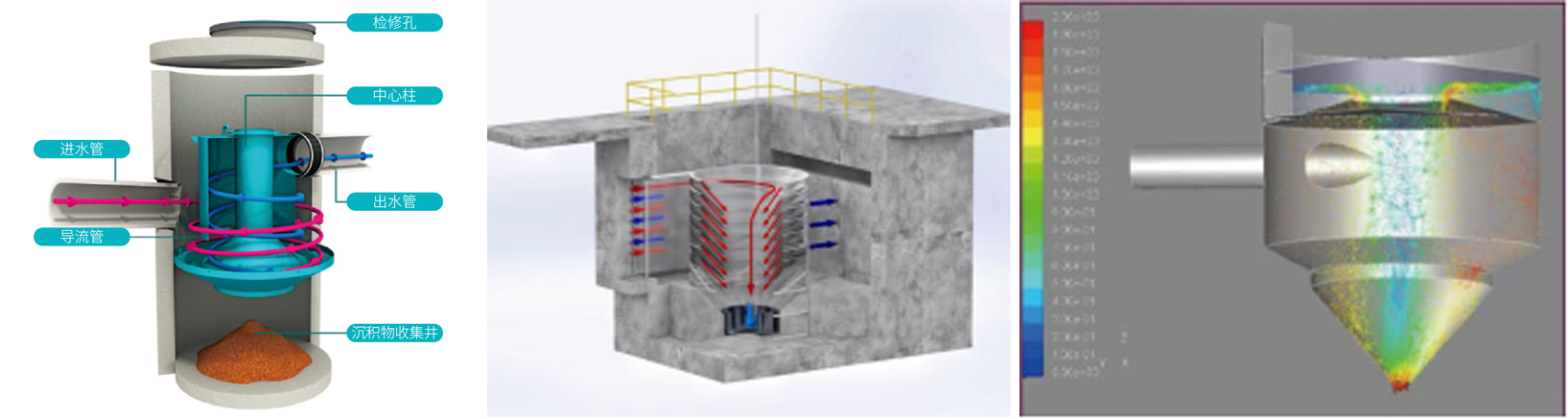

High-precision hydraulic grit removal technology is a kind of technology that utilizes the principle of vortex flow, adopts computational fluid dynamics to optimize the design, and makes use of the centrifugal force of water flow and gravity sedimentation to realize the efficient separation of pollutants. It constructs a new form of cyclone structure with more accurate flow control, which makes up for the shortcomings and deficiencies of the traditional desanding technology and can be customized according to the different needs of customers.

High-precision stacked disk desanding equipment adopts new structural design, the stacked disk is submerged in the concrete pool body, and the sewage after passing through the grating enters the pool body by the diversion pipe. The water distributor evenly distributes the sewage into each stacked disk, which enters tangentially along the stacked disk to form a cyclone. In the cyclone centrifugal action, gravel is thrown to the sewage and stacked disk interface in the boundary layer, while settling to the surface of the stacked disk and be captured. The settled gravel is flushed by the water flow into the center opening and subsequently collects in the bottom sand storage area. A sand pump periodically pumps the stored gravel to the outside of the tank. The unique multi-layer stacked disk structure provides a large enough contact area to remove fine gravel.

The Initial Stormwater Purification Equipment is an advanced hydrocyclone separation equipment, which can efficiently intercept sediments and floating materials through the unique inflow components and mud storage structure, and isolate the cyclone area, mud storage area, and slag storage area from each other, effectively preventing secondary pollution brought about by the disturbance of water flow.